Kawasaki Z1000SX - Service manual > Before Servicing

Kawasaki Z1000SX - Service manual > Before Servicing

Before starting to perform an inspection service or carry out a disassembly and reassembly operation on a motorcycle, read the precautions given below. To facilitate actual operations, notes, illustrations, photographs, cautions, and detailed descriptions have been included in each chapter wherever necessary. This section explains the items that require particular attention during the removal and reinstallation or disassembly and reassembly of general parts.

Especially note the following.

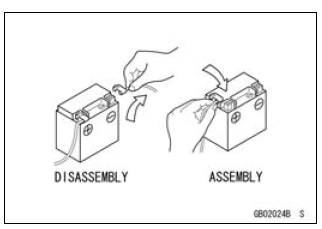

Battery Ground

Before completing any service on the motorcycle, disconnect the battery cables from the battery to prevent the engine from accidentally turning over. Disconnect the ground cable (-) first and then the positive (+). When completed with the service, first connect the positive (+) cable to the positive (+) terminal of the battery then the negative (-) cable to the negative terminal.

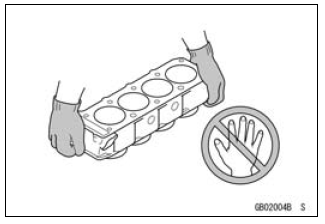

Edges of Parts

Lift large or heavy parts wearing gloves to prevent injury from possible sharp edges on the parts.

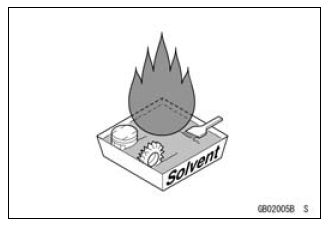

Solvent

Use a high-flush point solvent when cleaning parts. High-flush point solvent should be used according to directions of the solvent manufacturer.

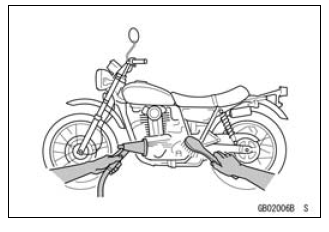

Cleaning Vehicle before Disassembly

Clean the vehicle thoroughly before disassembly. Dirt or other foreign materials entering into sealed areas during vehicle disassembly can cause excessive wear and decrease performance of the vehicle.

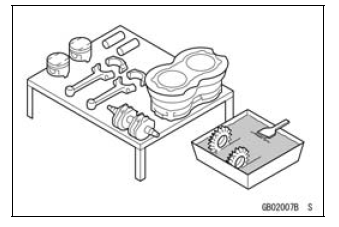

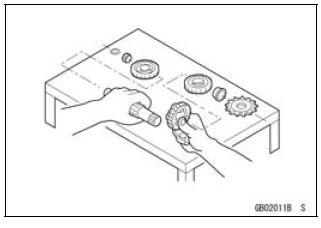

Arrangement and Cleaning of Removed Parts

Disassembled parts are easy to confuse. Arrange the parts according to the order the parts were disassembled and clean the parts in order prior to assembly.

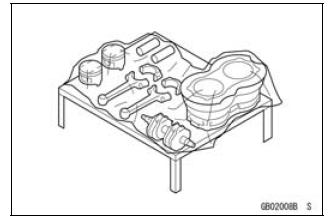

Storage of Removed Parts

After all the parts including subassembly parts have been cleaned, store the parts in a clean area. Put a clean cloth or plastic sheet over the parts to protect from any foreign materials that may collect before re-assembly.

Inspection

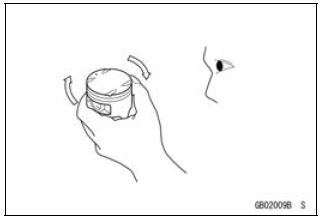

Reuse of worn or damaged parts may lead to serious accident.

Visually inspect removed parts for corrosion, discoloration, or other damage. Refer to the appropriate sections of this manual for service limits on individual parts. Replace the parts if any damage has been found or if the part is beyond its service limit.

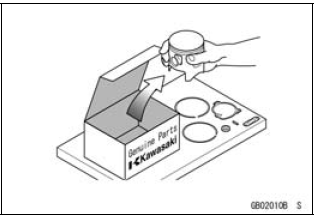

Replacement Parts

Replacement parts must be KAWASAKI genuine or recommended by KAWASAKI. Gaskets, O-rings, oil seals, grease seals, circlips, cotter pins or self-locking nuts must be replaced with new ones whenever disassembled.

Assembly Order

In most cases assembly order is the reverse of disassembly, however, if assembly order is provided in this Service Manual, follow the procedures given.

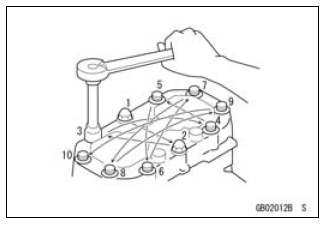

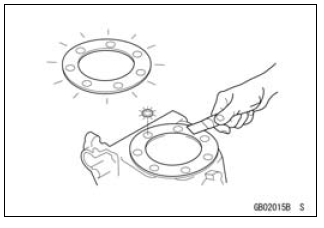

Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, start them all in their holes and tighten them to a snug fit. Then tighten them according to the specified sequence to prevent case warpage or deformation which can lead to malfunction. Conversely when loosening the bolts, nuts, or screws, first loosen all of them by about a quarter turn and then remove them. If the specified tightening sequence is not indicated, tighten the fasteners alternating diagonally.

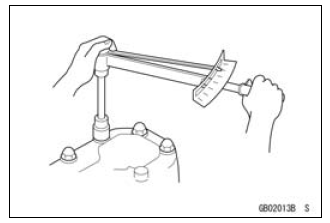

Tightening Torque

Incorrect torque applied to a bolt, nut, or screw may lead to serious damage. Tighten fasteners to the specified torque using a good quality torque wrench.

Force

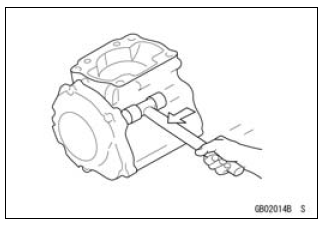

Use common sense during disassembly and assembly, excessive force can cause expensive or hard to repair damage.

When necessary, remove screws that have a non-permanent locking agent applied using an impact driver.

Use a plastic-faced mallet whenever tapping is necessary.

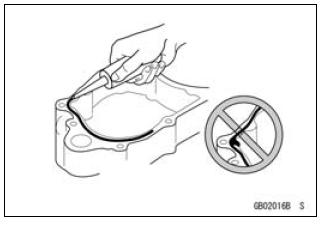

Gasket, O-ring

Hardening, shrinkage, or damage of both gaskets and O-rings after disassembly can reduce sealing performance.

Remove old gaskets and clean the sealing surfaces thoroughly so that no gasket material or other material remains.

Install the new gaskets and replace the used O-rings when re-assembling.

Liquid Gasket, Non-permanent Locking Agent

For applications that require Liquid Gasket or a Non-permanent Locking Agent, clean the surfaces so that no oil residue remains before applying liquid gasket or non-permanent locking agent. Do not apply them excessively.

Excessive application can clog oil passages and cause serious damage.

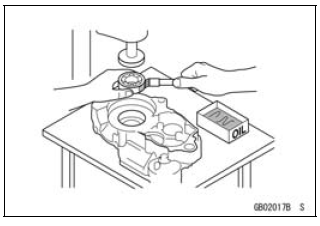

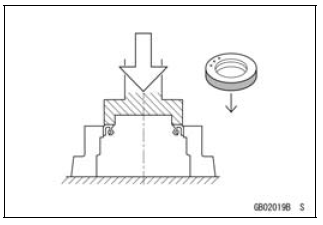

Press

For items such as bearings or oil seals that must be pressed into place, apply small amount of oil to the contact area. Be sure to maintain proper alignment and use smooth movements when installing.

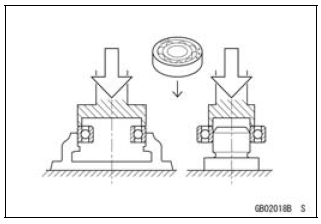

Ball Bearing and Needle Bearing

Do not remove pressed ball or needle unless removal is absolutely necessary. Replace with new ones whenever removed. Press bearings with the manufacturer and size marks facing out. Press the bearing into place by putting pressure on the correct bearing race as shown.

Pressing the incorrect race can cause pressure between the inner and outer race and result in bearing damage.

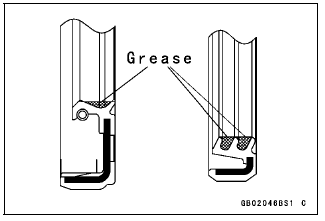

Oil Seal, Grease Seal

Do not remove pressed oil or grease seals unless removal is necessary. Replace with new ones whenever removed.

Press new oil seals with manufacture and size marks facing out. Make sure the seal is aligned properly when installing.

Apply specified grease to the lip of seal before installing the seal.

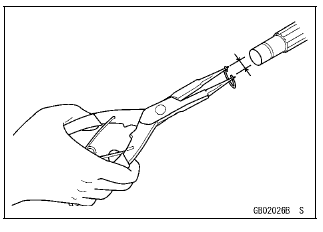

Circlips, Cotter Pins

Replace the circlips or cotter pins that were removed with new ones. Take care not to open the clip excessively when installing to prevent deformation.

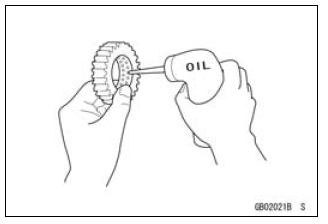

Lubrication

It is important to lubricate rotating or sliding parts during assembly to minimize wear during initial operation. Lubrication points are called out throughout this manual, apply the specific oil or grease as specified.

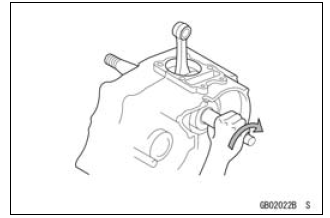

Direction of Engine Rotation

When rotating the crankshaft by hand, the free play amount of rotating direction will affect the adjustment. Rotate the crankshaft to positive direction (clockwise viewed from output side).

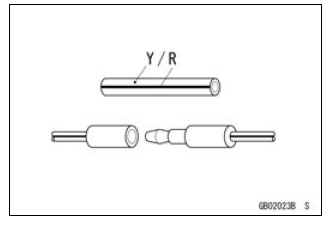

Electrical Wires

A two-color wire is identified first by the primary color and then the stripe color. Unless instructed otherwise, electrical wires must be connected to those of the same color.

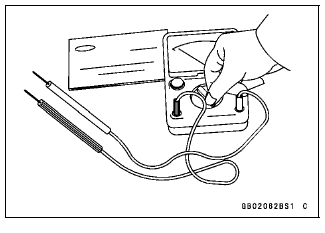

Instrument

Use a meter that has enough accuracy for an accurate measurement. Read the manufacture's instructions thoroughly before using the meter. Incorrect values may lead to improper adjustments.

See also:

Kawasaki Z1000SX - Service manual > Model Identification

Kawasaki Z1000SX - Service manual > Model Identification

ZX1000GB (United States and Canada) Left Side View ZX1000GB (United States and Canada) Right Side View

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07