Royal Enfield Interceptor 650 - Service manual > Clutch Components

Royal Enfield Interceptor 650 - Service manual > Clutch Components

Engine / Engine Inspection / Clutch Components

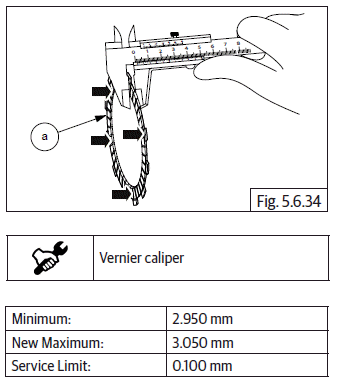

Friction plate

- Inspect the clutch plates visually for uneven wear, seizure and discoloration.

- Measure the thickness of the friction plate (a) at 4 locations marked by arrows.

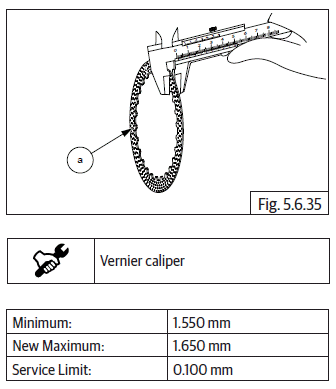

Steel Plate

- Measure the thickness of the steel plates (a) at different locations.

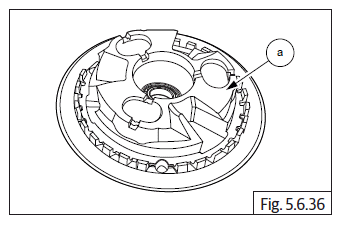

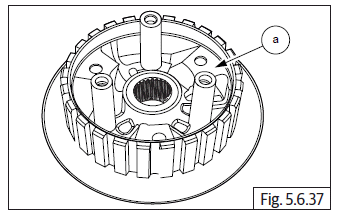

Clutch Hub (Outer and Inner)

- Inspect the clutch hub (a) for any scratches, wear or damage of the lugs.

- Visually inspect clutch center (a) for any scratches, wear or damage.

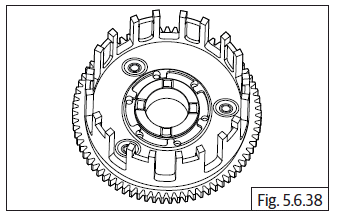

Clutch Housing

- Visually inspect clutch housing and lugs for any, wear, bends, lug breakage, heat marks or damages.

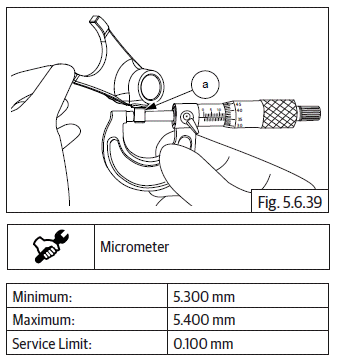

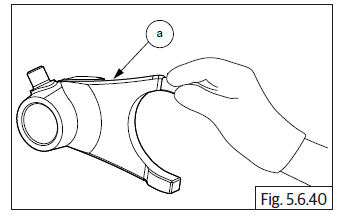

Shifter Forks

- Measure the pegs on shifter forks (a) using micrometer for wear.

- Visually inspect the shifter fork machined lugs (a) for damage, excessive wear out scoring and replace if damaged.

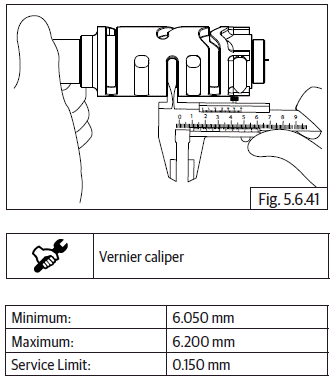

Selector Drum

- Inspect the shifter fork working grooves in the selector drum for any damages, chipped ends etc. Measure the grooves in their working area for excessive wear out.

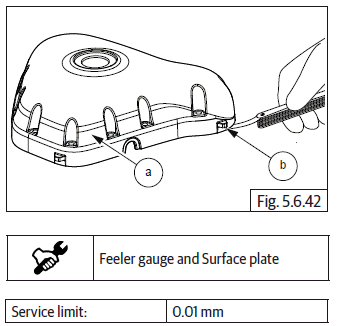

Magneto Cover

- Visually inspect the magneto cover for any outer damages, cracks etc.

- Inspect the cover seating area for any damages pitting etc.

- Place the magneto cover (a) on a surface plate and measure for any surface warpage using feeler strip (b) of 0.01 mm.

- Replace cover if warpage is beyond service limit.

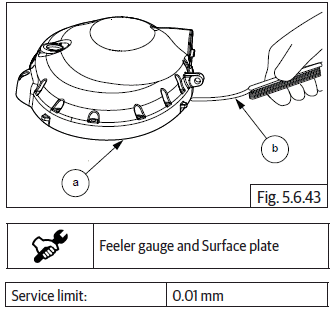

Clutch Cover

- Visually inspect the clutch cover for any outer damages, cracks etc.

- Inspect the cover seating area for any damages pitting etc.

- Place the clutch cover (a) on a surface plate and measure for any surface warpage using feeler strip (b) of 0.01 mm.

- Replace cover if warpage is beyond service limit.

See also:

Royal Enfield Interceptor 650 - Service manual > Cylinder Barrel

Royal Enfield Interceptor 650 - Service manual > Cylinder Barrel

Cylinder Barrel Bore ID Check cylinder bore to piston working area for scoring, seizure marks and/or excessive wear. Measure the cylinder bore at the top, middle and bottom at the rings working area using a bore gauge. Measure at both across and along the gudgeon pin axis.

Royal Enfield Interceptor 650 - Service manual > Journal Bearings Selection Chart

Royal Enfield Interceptor 650 - Service manual > Journal Bearings Selection Chart

Bearings Selection Procedure Crankshaft Journal Bearings Crankshaft journal bearings selection chart (1.1)

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07