Kawasaki Z1000SX - Service manual > DFI Parts Location, DFI Servicing Precautions

Kawasaki Z1000SX - Service manual > DFI Parts Location, DFI Servicing Precautions

DFI Parts Location

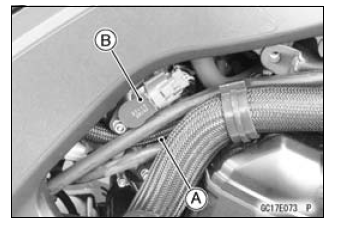

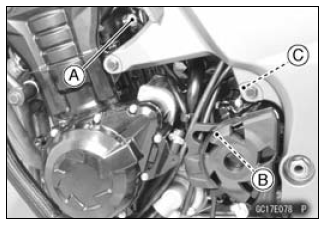

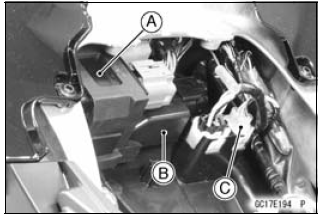

Main Throttle Sensor [A]

Subthrottle Sensor [B]

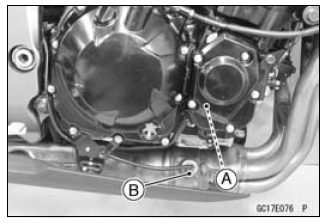

Crankshaft Sensor [A]

Oxygen Sensor [B] (Equipped Models)

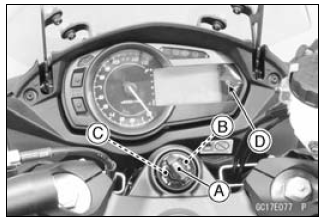

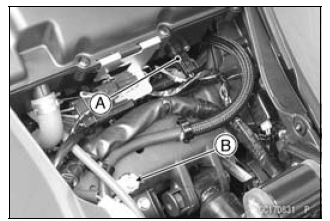

Ignition Key (Transponder, Equipped Models) [A]

Ignition Switch [B]

Immobilizer Antenna [C] (Equipped Models)

Warning Indicator Light (LED) [D]

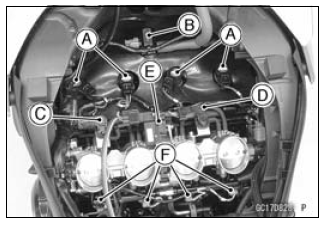

Stick Coils [A]

Air Switching Valve [B]

Intake Air Pressure Sensor #1 [C]

Intake Air Pressure Sensor #2 [D]

Subthrottle Valve Actuator [E]

Fuel Injectors [F]

Water Temperature Sensor [A]

Speed Sensor [B]

Engine Ground [C]

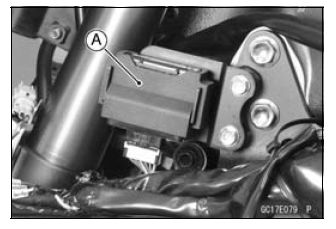

Immobilizer Amplifier [A] (Equipped Models)

Intake Air Temperature Sensor [A]

Frame Ground [B]

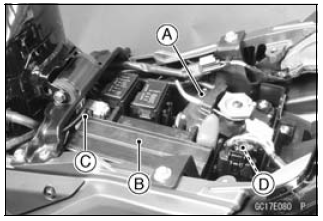

Exhaust Butterfly Valve Actuator [A]

Battery 12 V 8 Ah [B]

Vehicle-down Sensor [C]

FI Fuse 15 A [D]

Relay Box (ECU Main Relay, Radiator Fan Relay, Fuel Pump Relay) [A]

ECU [B]

Immobilizer (Equipped Models)/Kawasaki Diagnostic System Connector [C]

Fuel Pump [A]

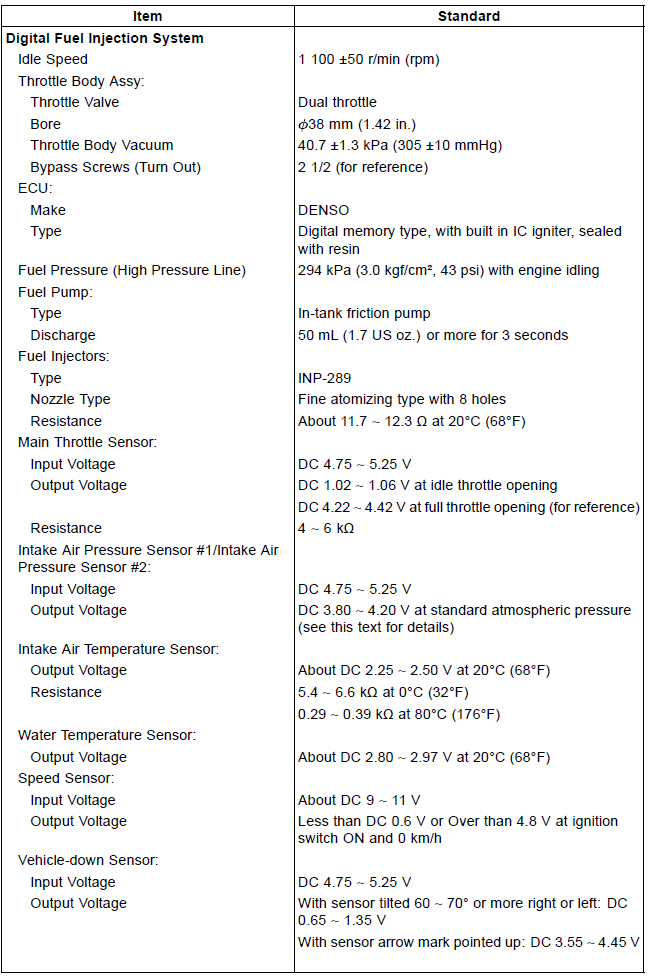

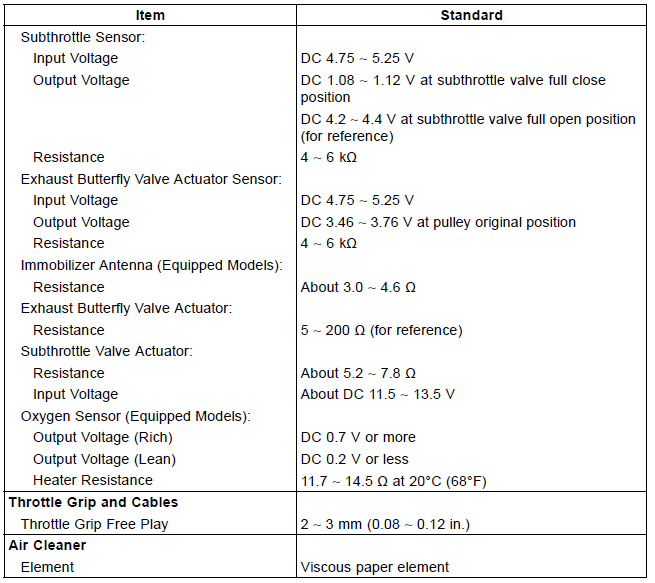

Specifications

Special Tools and Sealant

Oil Pressure Gauge, 5 kgf/cm²: 57001-125

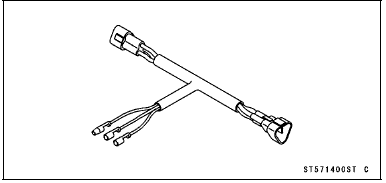

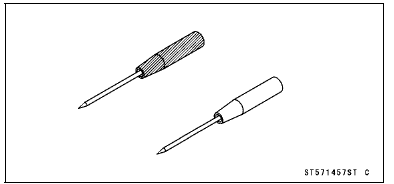

Throttle Sensor Setting Adapter #1: 57001-1400

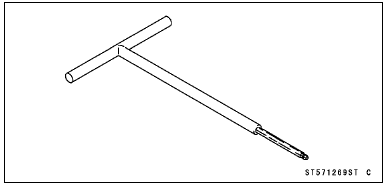

Carburetor Drain Plug Wrench, Hex 3: 57001-1269

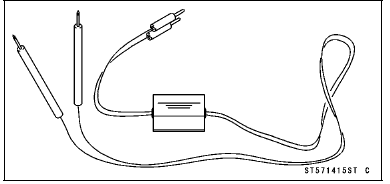

Peak Voltage Adapter: 57001-1415

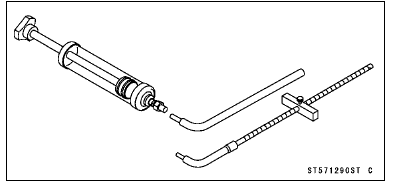

Fork Oil Level Gauge: 57001-1290

Needle Adapter Set: 57001-1457

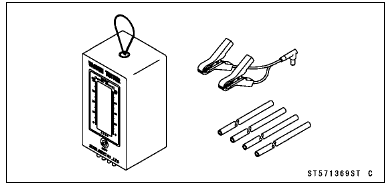

Vacuum Gauge: 57001-1369

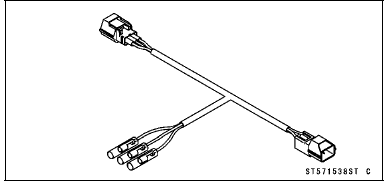

Throttle Sensor Setting Adapter: 57001-1538

Hand Tester: 57001-1394

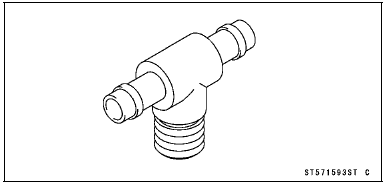

Fuel Pressure Gauge Adapter: 57001-1593

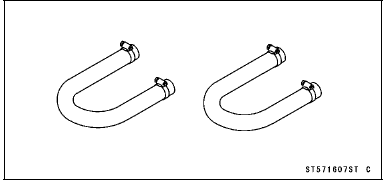

Fuel Hose: 57001-1607

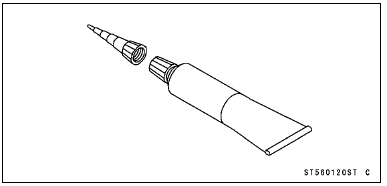

Liquid Gasket, TB1211: 56019-120

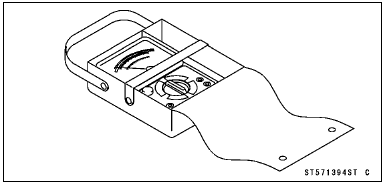

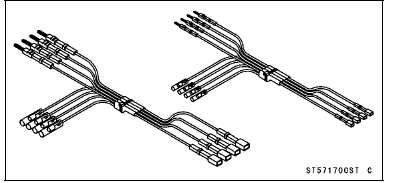

Measuring Adapter: 57001-1700

DFI Servicing Precautions

There are a number of important precautions that should be followed servicing the DFI system.

- This DFI system is designed to be used with a 12 V sealed battery as its power source. Do not use any other battery except for a 12 V sealed battery as a power source.

- Do not reverse the battery cable connections. This will damage the ECU.

- To prevent damage to the DFI parts, do not disconnect the battery cables or any other electrical connections when the ignition switch is ON, or while the engine is running.

- Take care not to short the leads that are directly connected to the battery positive (+) terminal to the chassis ground.

- When charging, remove the battery from the motorcycle.

This is to prevent ECU damage by excessive voltage.

- Whenever the DFI electrical connections are to be disconnected, first

turn off the ignition switch, and disconnect the battery (-) terminal. Do

not pull the lead, only the connector.

Conversely, make sure that all the DFI electrical connections are firmly reconnected before starting the engine.

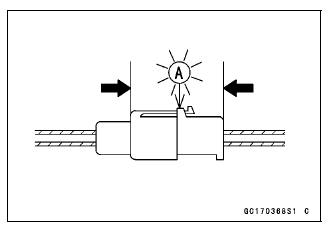

- Connect these connectors until they click [A].

- Do not turn the ignition switch ON while any of the DFI electrical connectors are disconnected. The ECU memorizes service codes.

- Do not spray water on the electrical parts, DFI parts, connectors, leads and wiring.

- If a transceiver is installed on the motorcycle, make sure that the operation of the DFI system is not influenced by electric wave radiated from the antenna. Check operation of the system with the engine at idle. Locate the antenna as far as possible away from the ECU.

- When any fuel hose is disconnected, do not turn on the ignition switch. Otherwise, the fuel pump will operate and fuel will spout from the fuel hose.

- Do not operate the fuel pump if the pump is completely dry. This is to prevent pump seizure.

- Before removing the fuel system parts, blow the outer surfaces of these parts clean with compressed air.

- When any fuel hose is disconnected, fuel may spout out by residual pressure in the fuel line. Cover the hose joint with a piece of clean cloth to prevent fuel spillage.

- When installing the fuel hoses, avoid sharp bending, kinking, flattening or twisting, and run the fuel hoses with a minimum of bending so that the fuel flow will not be obstructed.

- Run the hoses according to Cable, Wire, and Hose Routing section in the Appendix chapter.

- To prevent corrosion and deposits in the fuel system, do not add to fuel any fuel antifreeze chemicals.

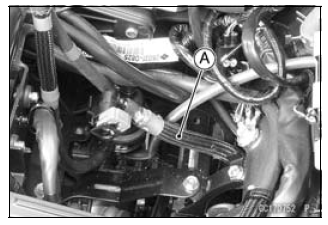

- If the motorcycle is not properly handled, the high pressure inside the

fuel line can cause fuel to leak or the hose to burst. Remove the fuel tank

(see Fuel Tank Removal) and check the fuel hose [A].

Replace the fuel hose if any fraying, cracks or bulges are noticed.

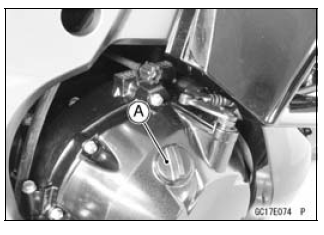

- To maintain the correct fuel/air mixture (F/A), there must be no intake air leaks in the DFI system. Be sure to install the oil filler plug [A] after filling the engine oil.

See also:

Kawasaki Z1000SX - Service manual > DFI System

Kawasaki Z1000SX - Service manual > DFI System

ECU Battery 12 V 8 Ah Air Switching Valve Intake Air Pressure Sensor #1 Intake Air Pressure Sensor #2 Crankshaft Sensor Subthrottle Valve Actuator Subthrottle Sensor Intake Air Temperature Sensor Main Throttle Sensor Water Temperature Sensor Fuel Injectors Delivery Pipe Assy Oxygen Sensor (Equipped Models) Exhaust Butterfly Valve Actuator Speed Sensor Fuel Pump Pressure Regulator Fuel Filter Vehicle-down Sensor Air Flow Fuel Flow

Kawasaki Z1000SX - Service manual > Troubleshooting the DFI System

Kawasaki Z1000SX - Service manual > Troubleshooting the DFI System

The warning indicator light (LED) [A] is used for the FI indicator, immobilizer indicator (equipped models) and oil pressure warning indicator.

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07