Royal Enfield Interceptor 650 - Service manual > Driveshaft Components

Royal Enfield Interceptor 650 - Service manual > Driveshaft Components

NOTE

- Do not resue thrust washers, circlips, collar bush. Always replace with new parts.

- Ensure each component is cleaned and lubricated with recommended lubricant.

- The driveshaft gears can be recognized by size: the gear with the smallest diameter is 6 th gear, and the one with largest is 1 st gear. Ensure that all parts are put back in correct sequence and all circlips and washers are incorporated in correct place.

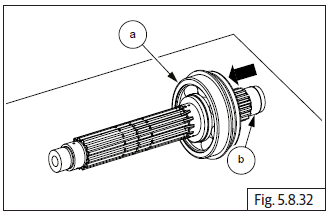

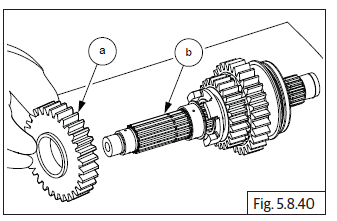

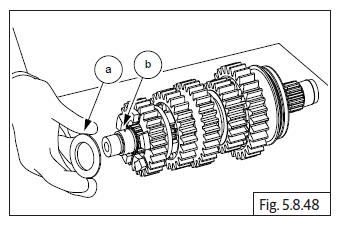

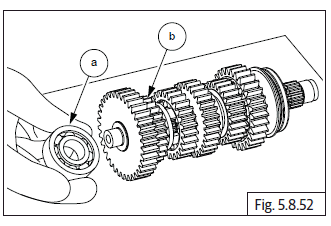

- Assemble ball bearing (a) on driveshaft (a) from short end and ensure it is fully seated against stopper on driveshaft.

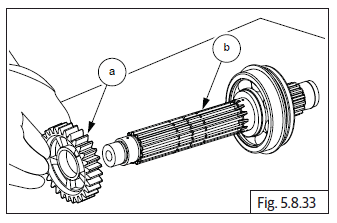

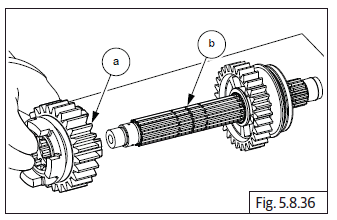

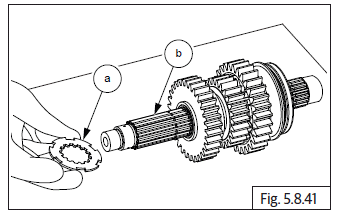

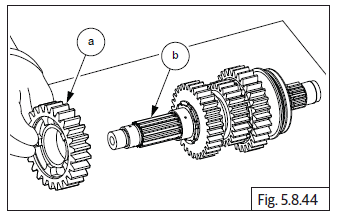

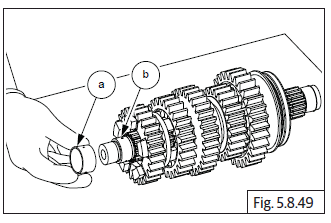

- Ensure machined surface of 2 nd gear is facing bearing and assemble 2 nd gear (a) on driveshaft (b) from the longer splines end.

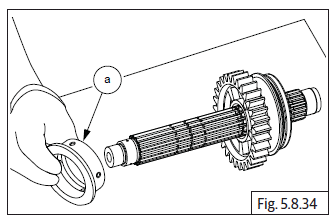

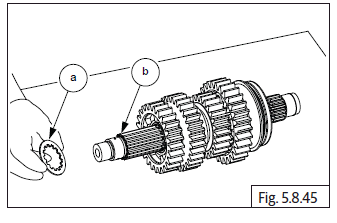

- Ensure collar on bush (a) is facing outside and assemble 2 nd gear collared bush on driveshaft. Ensure bush is seated properly inside 2 nd gear.

NOTE

- Ensure bush is seated properly inside 2 nd gear.

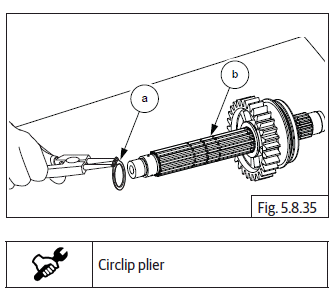

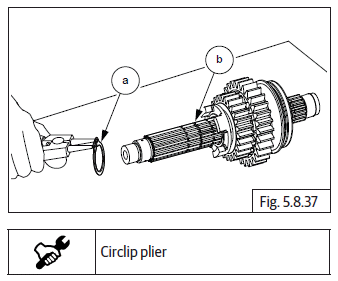

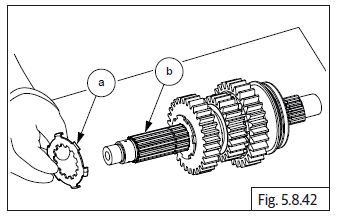

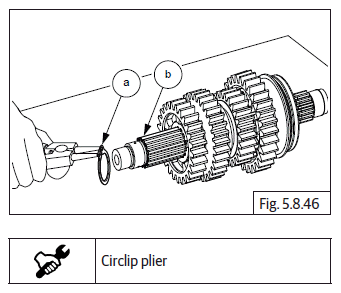

Assemble 1 st circlip (a) on innermost groove in driveshaft (b) and ensure it is seated properly on groove against 2 nd gear bush.

NOTE

- Gently rotate circlip without expanding to ensure it is properly seated in groove in driveshaft.

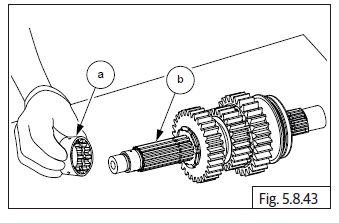

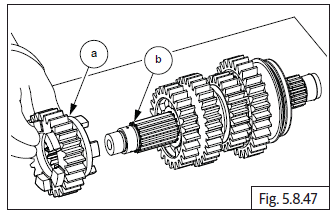

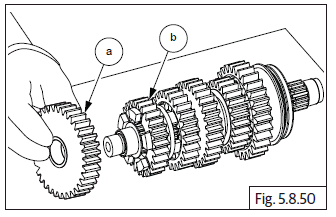

- Assemble 6 th gear (a) on driveshaft (b) ensuring lugs on larger face of gear are facing 2 nd gear.

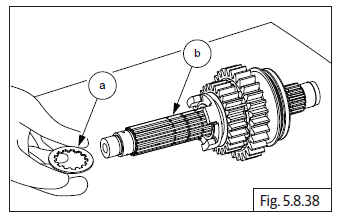

- Assemble 2 nd circlip (a) on inner groove on driveshaft (b) and ensure it is seated properly on groove.

NOTE

- Gently rotate circlip without expanding to ensure it is properly seated in groove in driveshaft.

- Assemble splined thrust washer (a) on driveshaft (b) and ensure it is seated properly against circlip.

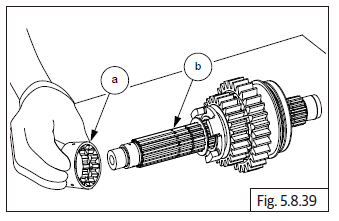

- Ensure oil hole in 1 st splined bush (a) is aligned with oil hole in driveshaft (b) and assemble splined bush on driveshaft.

NOTE

- Ensure bush is fully seated against thrust washer in driveshaft.

- Ensure collar on 3 rd gear (a) is facing outside and assemble 3 rd gear on driveshaft (b).

NOTE

- Ensure gear is fully seated on splined bush.

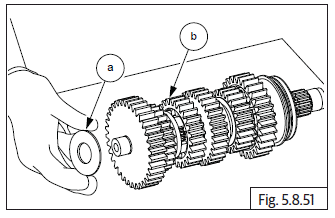

- Insert thrust lock washer (a) with internal and external splines on driveshaft (b) and align internal splines with groove in driveshaft.

- Rotate lock washer such that the washer locks in place on driveshaft and cannot come out.

- Assemble splined lock washer (a) on driveshaft (b) such that the outside tabs are facing the lock washer on driveshaft.

- Ensure outer tabs of lock washer are aligned and fully seated in outer splines of lock washer.

- Ensure oil hole in 2 nd splined bush (a) is aligned with oil hole in driveshaft (b) and assemble splined bush on driveshaft.

NOTE

- Ensure bush is fully seated against lock washer on driveshaft.

- Assemble 4 th gear (a) on the driveshaft (b) with its machined surface facing 3 rd gear and recessed lugs of 4 th gear facing outside.

- Ensure 4 th gear is seated fully on splined bush.

- Assemble 2 nd splined washer (a) on driveshaft (b) and ensure it is fully seated against 4 th gear.

NOTE

- Gently rotate circlip without expanding to ensure it is properly seated in groove in driveshaft.

- Assemble 3 rd circlip (a) on groove on driveshaft (b) and ensure circlip is properly seated in groove.

- Assemble 5 th gear (a) on driveshaft (b) with lugs facing 4 th gear.

- Assemble thrust washer (a) on driveshaft (b).

- Ensure oil hole in plain bush (a) is aligned with oil hole in driveshaft (b) and assemble plain bush on driveshaft.

NOTE

- Ensure the bush is fully seated against thrust washer on driveshaft.

- Ensure lugs seating surface of 1 st gear is facing lugs of 5 th gear; assemble 1 st gear (a) over bush on driveshaft (b). Ensure the 1 st gear is fully seated on bush.

- Assemble plain thrust washer (a) on driveshaft (b) and ensure it is fully seated against the 1 st gear.

- Assemble ball bearing (a) on driveshaft (b) and ensure it is properly seated against thrust washer on driveshaft.

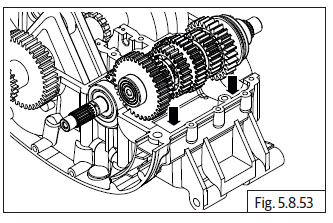

- Locate drive shaft assembly with gears on crankcase upper duly ensuring that the splines of the drive shaft are towards the LH side (Magneto side) of upper crankcase and the gears on counter shaft and drive shaft are properly meshed.

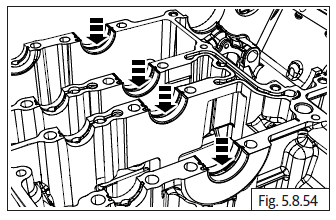

Journal bearings in lower crankcse

- Install crankshaft journal bearings into crankcase.

See also:

Royal Enfield Interceptor 650 - Service manual > Connecting Rods

Royal Enfield Interceptor 650 - Service manual > Connecting Rods

NOTE Ensure new journal bearings are located correctly in the connecting rods and caps. Connecting rod bolts are for one time use only. Do not reuse connecting rod bolts. Always replace them. Do not interchange connecting rod cap. Ensure the lug (a) in journal bearing is located in the grooves (b) on both connecting rod and cap is seated properly.

Royal Enfield Interceptor 650 - Service manual > Gear Shift Cam Drum

Royal Enfield Interceptor 650 - Service manual > Gear Shift Cam Drum

Assemble needle roller bearing (a) in lower crankcase (b) from the inside on LH side (Magneto side). Insert gear shift cam drum (c) into lower crankcase (b) from thr RH side (clutch side), duly ensuring the 2 pegs to the gear shift cam drum are towards the RH side (clutch side). Assemble big bearing (a) on lower crankcase RH side (b) (clutch side) over the gear shift cam drum. Gently tap on the bearing (a) to press fit with crankcase (b).

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07