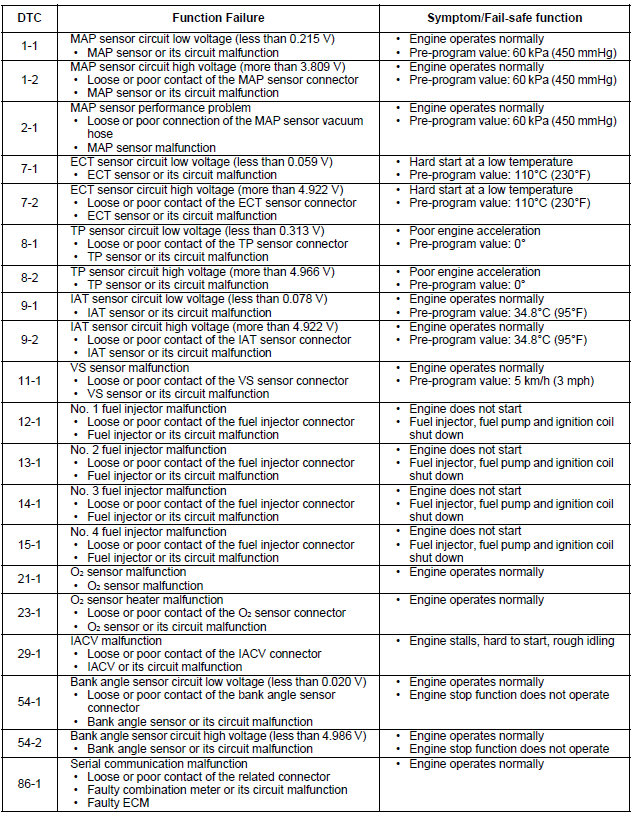

Honda CBR650 - Service manual > DTC index

Honda CBR650 - Service manual > DTC index

NOTE:

- If the MCS is not used, perform all of the inspection on the corresponding main code (digits in front of hyphen) of the DTC.

DTC troubleshooting

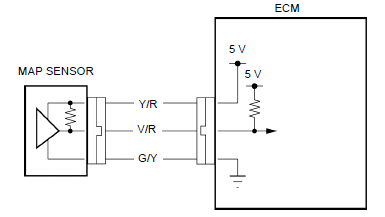

DTC 1 (MAP SENSOR)

Probable cause

- Open circuit in Yellow/red or Green/yellow wire between the MAP sensor and ECM

- Open or short circuit in Violet/red wire between the MAP sensor and ECM

- Faulty MAP sensor

- Faulty ECM

DTC 1-1 (MAP SENSOR LOW VOLTAGE)

1. MAP Sensor System Inspection

Check the MAP sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

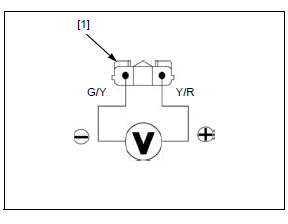

2. MAP Sensor Input Voltage Inspection

Turn the ignition switch OFF.

Disconnect the MAP sensor 3P (Black) connector.

Turn the ignition switch ON with the engine stop switch " ".

".

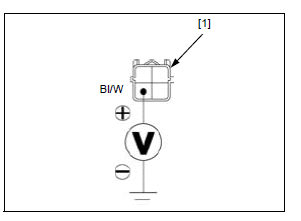

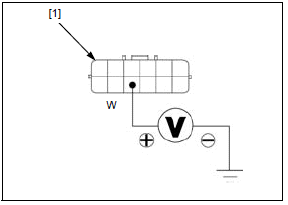

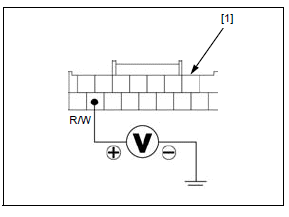

Measure the voltage between the wire harness side MAP sensor 3P (Black) connector [1] terminals.

CONNECTION: Yellow/red (+) - Green/yellow (-)

STANDARD: 4.75 - 5.25 V

Is the voltage within standard value?

YES - GO TO STEP 4.

NO - GO TO STEP 3.

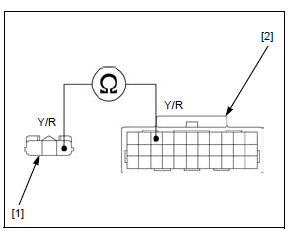

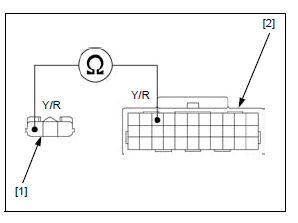

3. MAP Sensor Input Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) connector.

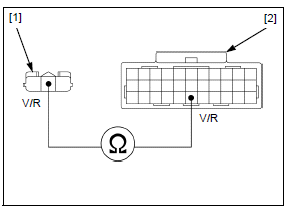

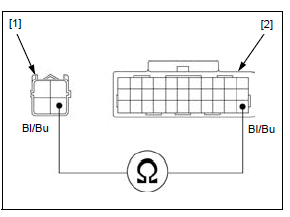

Check for continuity between the wire harness side MAP sensor 3P (Black) connector [1] and ECM 33P (Black) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Yellow/red - Yellow/red

Is there continuity?

YES - Replace the ECM with a known good one, and recheck.

NO - Open circuit in Yellow/red wire

4. MAP Sensor Signal Line Short Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) connector.

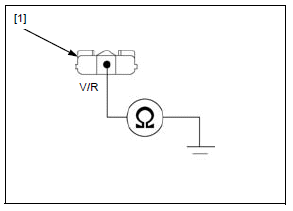

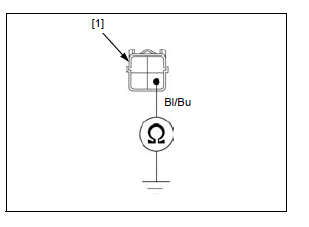

Check for continuity between MAP sensor 3P (Black) connector [1] terminal and ground.

CONNECTION: Violet/red - Ground

Is there continuity?

YES - Short circuit in Violet/red wire

NO - GO TO STEP 5.

5. MAP Sensor Inspection

Replace the MAP sensor with a known good one.

Connect the ECM 33P (Black) connector.

Erase the DTC.

Check the MAP sensor with the MCS.

Is DTC 1-1 indicated?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty original MAP sensor

DTC 1-2 (MAP SENSOR HIGH VOLTAGE)

- Before starting the inspection, check for loose or poor contact on the MAP sensor 3P (Black) and ECM 33P (Gray) connectors, and recheck the DTC.

1. MAP Sensor System Inspection.

Check the MAP sensor with the MCS.

Is about 5 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. MAP Sensor Input Voltage Inspection.

Turn the ignition switch OFF.

Disconnect the MAP sensor 3P (Black) connector.

Turn the ignition switch ON with the engine stop switch " ".

".

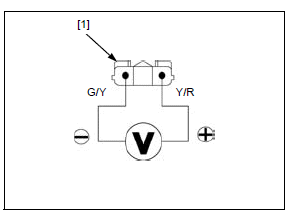

Measure the voltage between the wire harness side MAP sensor 3P (Black) connector [1] terminals.

CONNECTION: Yellow/red (+) - Green/yellow (-)

STANDARD: 4.75 - 5.25 V

Is the voltage within standard value?

YES - GO TO STEP 3.

NO - Open circuit in Green/yellow wire

3. MAP Sensor System Inspection with Jumper Wire.

Turn the ignition switch OFF.

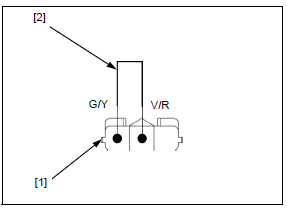

Connect the wire harness side MAP sensor 3P (Black) connector [1] terminals with a jumper wire [2].

CONNECTION: Violet/red - Green/yellow

Check the MAP sensor with the MCS.

Is about 0 V indicated?

YES - Faulty MAP sensor

NO - GO TO STEP 4.

4. MAP Sensor Signal Line Open Circuit Inspection.

Turn the ignition switch OFF.

Disconnect the ECM 33P (Gray) connector.

Check for continuity between the wire harness side MAP sensor 3P (Black) connector [1] and ECM 33P (Gray) connector [2] terminals.

TOOL: Test probe 07ZAJ-RDJA110

CONNECTION: Violet/red - Violet/red

Is there continuity?

YES - Replace the ECM with a known good one, and recheck.

NO - Open circuit in Violet/red wire

DTC 2 (MAP SENSOR)

Probable cause

- Loose or poor connection of the MAP sensor vacuum hose

- Faulty MAP sensor

- Faulty ECM

DTC 2-1 (MAP SENSOR)

1. MAP Sensor System Inspection

Start the engine and check the MAP sensor with the MCS at idle speed.

Is the reading changed?

YES - Intermittent failure

NO - GO TO STEP 2.

2. Manifold Absolute Pressure Test

Stop the engine.

Lift the fuel tank and support it.

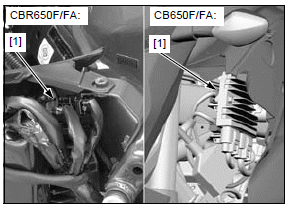

Check for connection and installation of the MAP sensor vacuum hose [1].

Is the MAP sensor vacuum hose connection correct?

YES - GO TO STEP 3.

NO - Correct the hose installation.

3. MAP Sensor System Inspection.

Replace the MAP sensor with a known good one.

Start the engine.

Check the MAP sensor with the MCS at idle speed.

Is the reading changed?

YES - Faulty original MAP sensor

NO - Replace the ECM with a known good one and recheck.

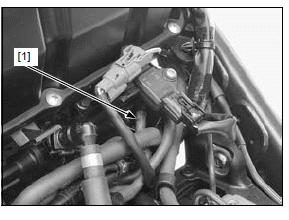

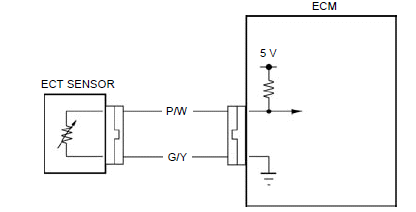

DTC 7 (ECT SENSOR)

Probable cause

- Open or short circuit in Pink/white wire between the ECT sensor and ECM

- Open circuit in Green/yellow wire between the ECT sensor and ECM

- Faulty ECT sensor

- Faulty ECM

DTC 7-1 (ECT SENSOR LOW VOLTAGE)

1. ECT Sensor System Inspection

Check the ECT sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. ECT Sensor System Inspection with Connector Disconnected

Turn the ignition switch OFF.

Disconnect the ECT sensor 2P (Blue) connector.

Check the ECT sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 3.

NO - Faulty ECT sensor

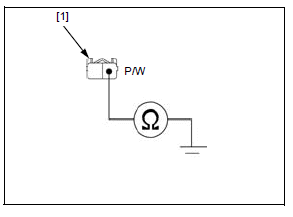

3. ECT Sensor Output Line Short Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Gray) connector.

Check for continuity between the wire harness side ECT sensor 2P (Blue) connector [1] terminal and ground.

CONNECTION: Pink/white - Ground

Is there continuity?

YES - Short circuit in Pink/white wire

NO - Replace the ECM with a known good one, and recheck.

DTC 7-2 (ECT SENSOR HIGH VOLTAGE)

- Before starting the inspection, check for loose or poor contact on the ECT sensor 2P (Blue), ECM 33P (Black) and 33P (Gray) connectors, and recheck the DTC.

1. ECT Sensor System Inspection

Check the ECT sensor with the MCS.

Is about 5 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

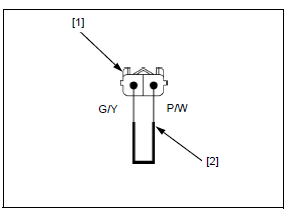

2. ECT Sensor System Inspection with Jumper Wire

Turn the ignition switch OFF.

Disconnect the ECT sensor 2P (Blue) connector.

Connect the wire harness side ECT sensor 2P (Blue) connector [1] terminals with a jumper wire [2].

CONNECTION: Pink/white - Green/yellow

Check the ECT sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 4.

NO - GO TO STEP 3.

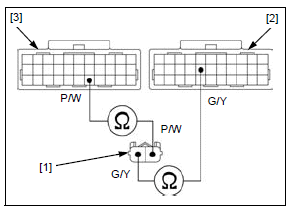

3. ECT Sensor Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) and 33P (Gray) connectors.

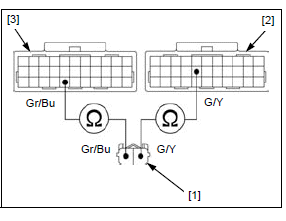

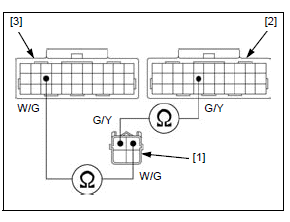

Check for continuity between the wire harness side ECT sensor 2P (Blue) connector [1] and ECM 33P (Black) [2] and 33P (Gray) [3] connector terminals.

TOOL: Test probe 07ZAJ-RDJA110

CONNECTION:

Pink/white - Pink/white

Green/yellow - Green/yellow

Is there continuity?

YES - Replace the ECM with a known good one, and recheck.

NO -

- Open circuit in Pink/white wire

- Open circuit in Green/yellow wire

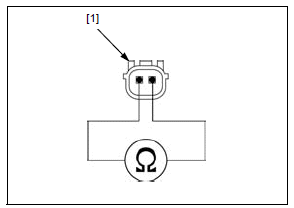

4. ECT Sensor Resistance Inspection

Turn the ignition switch OFF.

Remove the ECT sensor.

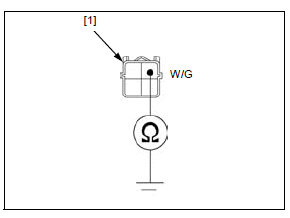

Measure the resistance between the 2P connector terminals of the ECT sensor [1].

STANDARD: 1.0 - 1.3 kΩ (40ºC/104ºF)

Is the resistance within standard value?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty ECT sensor

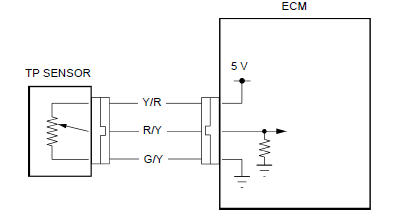

DTC 8 (TP SENSOR)

Probable cause

- Open circuit in Yellow/red or Green/yellow wire between the TP sensor and ECM

- Open or short circuit in Red/yellow wire between the TP sensor and ECM

- Short circuit between Yellow/red and Red/yellow wires

- Faulty TP sensor

- Faulty ECM

DTC 8-1 (TP SENSOR LOW VOLTAGE)

- Before starting the inspection, check for loose or poor contact on the TP sensor 3P (Blue), ECM 33P (Black) and 33P (Gray) connectors, and recheck the DTC.

1. TP Sensor System Inspection

Check the TP sensor with the MCS with the throttle fully closed.

Is about 0 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

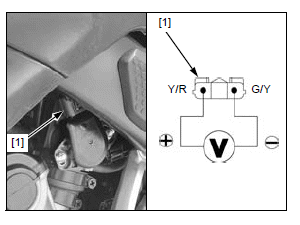

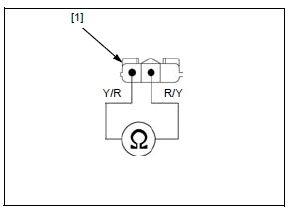

2. TP Sensor Input Voltage Inspection

Turn the ignition switch OFF.

Disconnect the TP sensor 3P (Blue) connector [1].

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side TP sensor 3P (Blue) connector terminals.

CONNECTION: Yellow/red (+) - Green/yellow (-)

STANDARD: 4.75 - 5.25 V

Is the voltage within standard value?

YES - GO TO STEP 4.

NO - GO TO STEP 3.

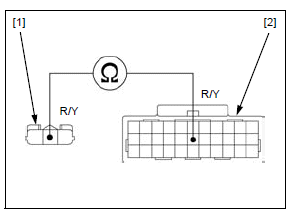

3. TP Sensor Input Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) connector.

Check for continuity between the wire harness side TP sensor 3P (Blue) connector [1] and ECM 33P (Black) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Yellow/red - Yellow/red

Is there continuity?

YES - Replace the ECM with a known good one, and recheck.

NO - Open circuit in Yellow/red wire

4. TP Sensor Signal Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Gray) connector.

Check for continuity between the wire harness side TP sensor 3P (Blue) connector [1] and ECM 33P (Gray) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Red/yellow - Red/yellow

Is there continuity?

YES - GO TO STEP 5.

NO - Open circuit in Red/yellow wire

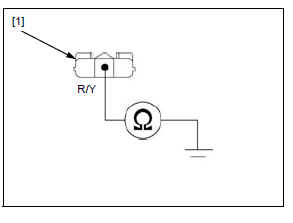

5. TP Sensor Signal Line Short Circuit Inspection

Check for continuity between the wire harness side TP sensor 3P (Blue) connector [1] terminal and ground.

CONNECTION: Red/yellow - Ground

Is there continuity?

YES - Short circuit in Red/yellow wire

NO - GO TO STEP 6.

6. TP Sensor Inspection

Replace the throttle body (TP sensor) with a known good one.

Connect the ECM 33P (Gray) connector.

Erase the DTC.

Check the TP sensor with the MCS.

Is DTC 8-1 indicated?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty original TP sensor

DTC 8-2 (TP SENSOR HIGH VOLTAGE)

1. TP Sensor System Inspection

Check the TP sensor with the MCS.

Is about 5 V indicated?

YES - GO TO STEP 3.

NO - GO TO STEP 2.

2. TP Sensor System Inspection with throttle operated

Check that the TP sensor voltage increases continuously when moving the throttle from fully closed position to fully opened position using the data list menu of the MCS.

Is the voltage increase continuously?

YES - Intermittent failure

NO - Faulty TP sensor

3. TP Sensor Input Voltage Inspection

Turn the ignition switch OFF.

Disconnect the TP sensor 3P (Blue) connector [1].

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side TP sensor 3P (Blue) connector terminals.

CONNECTION: Yellow/red (+) - Green/yellow (-)

STANDARD: 4.75 - 5.25 V

Is the voltage within standard value?

YES - GO TO STEP 4.

NO - Open circuit in Green/yellow wire

4. TP Sensor Line Short Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) and 33P (Gray) connectors.

Check for continuity between the wire harness side TP sensor 3P (Blue) connector [1] terminals.

CONNECTION: Yellow/red - Red/yellow

Is there continuity?

YES - Short circuit between Yellow/red and Red/ yellow wires

NO - GO TO STEP 5.

5. TP Sensor Inspection

Replace the throttle body (TP sensor) with a known good one.

Connect the ECM 33P connectors.

Erase the DTC.

Check the TP sensor with the MCS.

Is DTC 8-2 indicated?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty original TP sensor

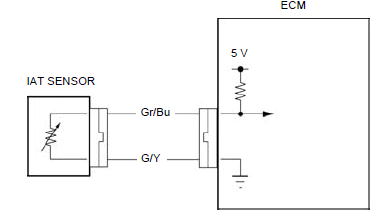

DTC 9 (IAT SENSOR)

Probable cause

- Open or short circuit in Gray/blue wire between the IAT sensor and ECM

- Open circuit in Green/yellow wire between the IAT sensor and ECM

- Faulty IAT sensor

- Faulty ECM

DTC 9-1 (IAT SENSOR LOW VOLTAGE)

1. IAT Sensor System Inspection

Check the IAT sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. IAT Sensor System Inspection with Connector Disconnected

Turn the ignition switch OFF.

Disconnect the IAT sensor 2P (Black) connector.

Check the IAT sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 3.

NO - Faulty IAT sensor

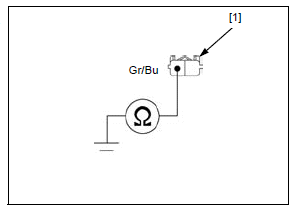

3. IAT Sensor Output Line Short Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Gray) connector.

Check for continuity between the wire harness side IAT sensor 2P (Black) connector [1] terminal and ground.

CONNECTION: Gray/blue - Ground

Is there continuity?

YES - Short circuit in Gray/blue wire

NO - Replace the ECM with a known good one, and recheck.

DTC 9-2 (IAT SENSOR HIGH VOLTAGE)

- Before starting the inspection, check for loose or poor contact on the IAT sensor 2P (Black), ECM 33P (Black) and 33P (Gray) connectors, and recheck the DTC.

1. IAT Sensor System Inspection

Check the IAT sensor with the MCS.

Is about 5 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

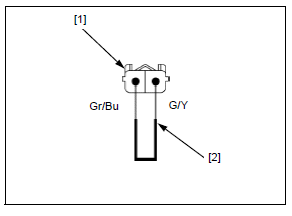

2. IAT Sensor System Inspection with Jumper Wire

Turn the ignition switch OFF.

Disconnect the IAT sensor 2P (Black) connector.

Connect the wire harness side IAT sensor 2P (Black) connector [1] terminals with a jumper wire [2].

CONNECTION: Gray/blue - Green/yellow

Check the IAT sensor with the MCS.

Is about 0 V indicated?

YES - Faulty IAT sensor

NO - GO TO STEP 3.

3. IAT Sensor Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the ECM 33P (Black) and 33P (Gray) connectors.

Check for continuity between the wire harness side IAT sensor 2P (Black) connector [1] and ECM 33P (Black) [2]/33P (Gray) [3] connector terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

Gray/blue - Gray/blue

Green/yellow - Green/yellow

Is there continuity?

YES - GO TO STEP 4.

NO -

- Open circuit in Gray/blue wire

- Open circuit in Green/yellow wire

4. IAT Sensor Resistance Inspection

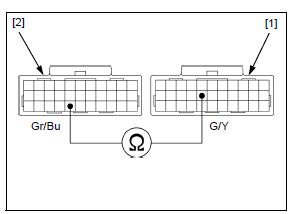

Connect the IAT sensor 2P (Black) connector.

Measure the resistance between the wire harness side ECM 33P (Black) [1] and 33P (Gray) [2] connector terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Gray/blue - Green/yellow

STANDARD: 1 - 4 kΩ (20ºC/68ºF)

Is the resistance within standard value?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty IAT sensor

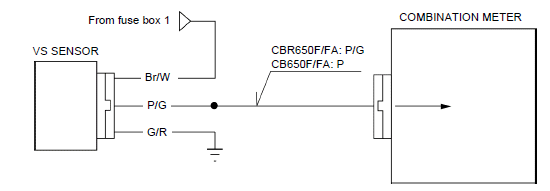

DTC 11 (VS SENSOR)

Probable cause

- Open circuit in Brown/white wire between the fuse box 1 and VS sensor

- Open circuit in Green/red wire between the VS sensor and ground

- Open or short circuit in Pink/green wire between the VS sensor and combination meter

- Faulty VS sensor

- Faulty combination meter

DTC 11-1 (VS SENSOR)

- Before starting the inspection, check for loose or poor contact on the VS sensor 3P (Black) and combination meter 16P (Gray) connectors, and recheck the DTC.

1. Recheck DTC

Erase the DTC.

Test-ride the motorcycle above 3,800 min-1 (rpm).

Stop the engine.

Check the VS sensor with the MCS.

Is DTC 11-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

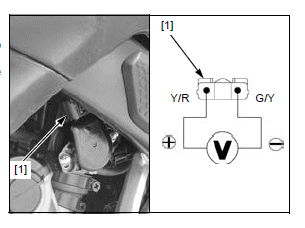

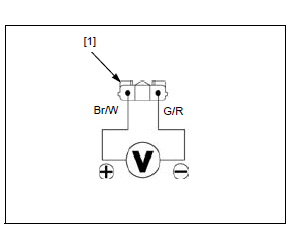

2. VS Sensor Input Voltage Inspection

Turn the ignition switch OFF.

Disconnect the VS sensor 3P (Black) connector.

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side VS sensor 3P (Black) connector [1] terminals.

CONNECTION: Brown/white (+) - Green/red (-)

YES - GO TO STEP 3.

NO -

- Open circuit in Brown/white wire

- Open circuit in Green/red wire

3. VS Sensor Signal Line Short Circuit Inspection

Turn the ignition switch OFF.

Check for continuity between the wire harness side VS sensor 3P (Black) connector [1] terminal and ground.

CONNECTION: Pink/green - Ground

Is there continuity?

YES - Short circuit in Pink/green wire

NO - GO TO STEP 4.

4. VS Sensor Signal Line Open Circuit Inspection

Disconnect the combination meter 16P (Gray) connector as the combination meter power/ground line inspection.

Check for continuity between the wire harness side VS sensor 3P (Black) connector [1] and combination meter 16P (Gray) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

CBR650F/FA: Pink/green - Pink/green

CB650F/FA: Pink/green - Pink

Is there continuity?

YES - GO TO STEP 5.

NO -

- CBR650F/FA: Open circuit in Pink/ green wire

- CB650F/FA: Open circuit in Pink/green or Pink wire

5. VS Sensor Inspection

Replace the VS sensor with a known good one.

Connect the combination meter 16P (Gray) connector.

Erase the DTC.

Test-ride the motorcycle above 3,800 min-1 (rpm).

Stop the engine.

Check the DTC with the MCS.

Is DTC 11-1 indicated?

YES - Replace the combination meter with a known good one, and recheck.

NO - Faulty original VS sensor

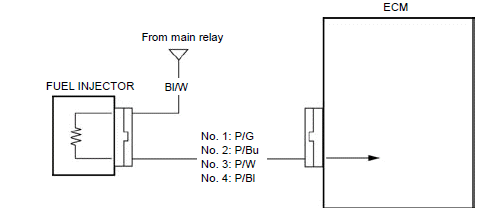

DTC 12 (No. 1 FUEL INJECTOR)/

DTC 13 (No. 2 FUEL INJECTOR)/

DTC 14 (No. 3 FUEL INJECTOR)/

DTC 15 (No. 4 FUEL INJECTOR)

Probable cause

- Open circuit in Black/white wire between the main relay and fuel injector

- Open or short circuit in Pink/green (No. 1) or Pink/ blue (No. 2) or Pink/white (No. 3) or Pink/black (No.4) wire between the fuel injector and ECM

- Faulty fuel injector

- Faulty ECM

DTC 12-1 (No. 1 FUEL INJECTOR)/

DTC 13-1 (No. 2 FUEL INJECTOR)/

DTC 14-1 (No. 3 FUEL INJECTOR)/

DTC 15-1 (No. 4 FUEL INJECTOR)

- Before starting the inspection, check for loose or poor contact on the fuel injector 2P (Black) and ECM 33P (Black) connectors, and recheck the DTC.

1. Recheck DTC

Erase the DTC.

Start the engine and check the fuel injector with the MCS.

Is the DTC 12-1, 13-1, 14-1 or 15-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. Fuel Injector Input Voltage Inspection

Turn the ignition switch OFF.

Lift the fuel tank and support it.

Disconnect the fuel injector 2P (Black) connector.

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side injector 2P (Black) connector [1] terminal and ground.

CONNECTION: Black/white (+) - Ground (-)

Is there battery voltage?

YES - GO TO STEP 3.

NO - Open circuit in Black/white wire

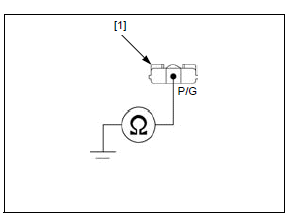

3. Fuel Injector Resistance Inspection

Turn the ignition switch OFF.

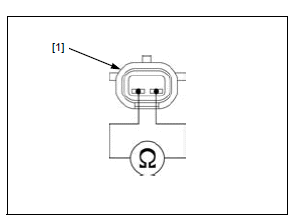

Measure the resistance between the 2P connector terminals of the fuel injector [1].

STANDARD: 11 - 13 Ω (20ºC/68ºF)

Is the resistance within standard value?

YES - GO TO STEP 4.

NO - Faulty fuel injector

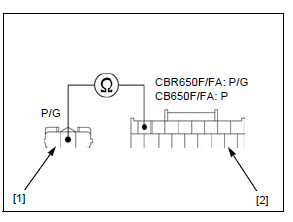

4. Fuel Injector Signal Line Open Circuit Inspection

Disconnect the ECM 33P (Black) connector.

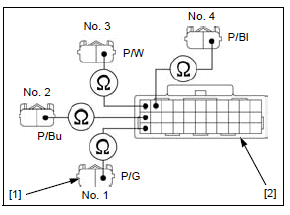

Check for continuity between the wire harness side fuel injector 2P (Black) connector [1] and ECM 33P (Black) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

No. 1: Pink/green - Pink/green

No. 2: Pink/blue - Pink/blue

No. 3: Pink/white - Pink/white

No. 4: Pink/black - Pink/black

Is there continuity?

YES - GO TO STEP 5.

NO -

- Open circuit in Pink/green wire

- Open circuit in Pink/blue wire

- Open circuit in Pink/white wire

- Open circuit in Pink/black wire

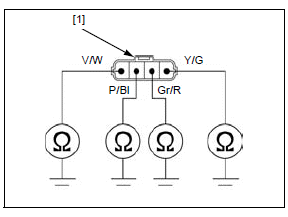

5. Fuel Injector Signal Line Short Circuit Inspection

Check for continuity between the wire harness side injector 2P (Black) connector [1] terminal and ground.

CONNECTION:

No. 1: Pink/green - Ground

No. 2: Pink/blue - Ground

No. 3: Pink/white - Ground

No. 4: Pink/black - Ground

Is there continuity?

YES -

- Short circuit in Pink/green wire

- Short circuit in Pink/blue wire

- Short circuit in Pink/white wire

- Short circuit in Pink/black wire

NO - Replace the ECM with a known good one, and recheck.

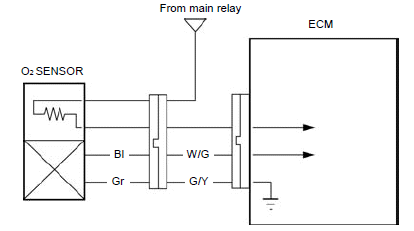

DTC 21 (O2 SENSOR)

Probable cause

- Open or short circuit in White/green wire between the ECM and O2 sensor

- Open circuit in Green/yellow wire between the O2 sensor and ECM

- Faulty O2 sensor

- Faulty ECM

DTC 21-1 (O2 Sensor)

- Before starting the inspection, check for loose or poor contact on the O2 sensor 4P (Black), ECM 33P (Black) and 33P (Gray) connectors, and recheck the DTC.

1. Recheck DTC

Erase the DTC.

Start the engine and warm it up until the coolant temperature is 80ºC (176ºF).

Stop the engine.

Check the O2 sensor with the MCS.

Is the DTC 21-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

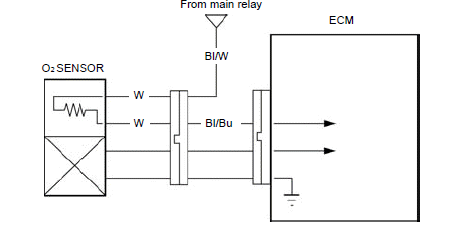

2. O2 Sensor Line Open Circuit Inspection

Turn the ignition switch OFF.

Disconnect the following:

- O2 sensor 4P (Black) connector.

- ECM 33P (Black)/33P (Gray) connectors.

Check for continuity between the wire harness side O2 sensor 4P (Black) connector [1] and ECM 33P (Black) [2]/33P (Gray) [3] connector terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

White/green - White/green

Green/yellow - Green/yellow

Is there continuity?

YES - GO TO STEP 3.

NO - Open circuit in White/green or Green/ yellow wire

3. O2 Sensor Output Line Short Circuit Inspection

Check the continuity between the wire harness side O2 sensor 4P (Black) connector [1] terminal and ground.

CONNECTION: White/green - Ground

Is there continuity?

YES - Short circuit in White/green wire

NO - GO TO STEP 4.

4. O2 Sensor Inspection

Replace the O2 sensor with a known good one.

Connect the ECM 33P connectors.

Erase the DTC.

Start the engine and warm it up until the coolant temperature is 80ºC (176ºF).

Stop the engine.

Check the O2 sensor with the MCS.

Is the DTC 21-1 indicated?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty original O2 sensor

DTC 23 (O2 SENSOR HEATER)

Probable cause

- Open circuit in Black/white wire between the main relay and O2 sensor

- Open or short circuit in White or Black/blue wire between the O2 sensor and ECM

- Faulty O2 sensor

- Faulty ECM

DTC 23-1 (O2 SENSOR HEATER)

- Before starting the inspection, check for loose or poor contact on the O2 sensor 4P (Black) and ECM 33P (Gray) connectors, and recheck the DTC.

1. Recheck DTC

Erase the DTC.

Start the engine and check the O2 sensor heater with the MCS.

Is DTC 23-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. O2 Sensor Heater Resistance Inspection

Turn the ignition switch OFF.

Disconnect the O2 sensor 4P (Black) connector.

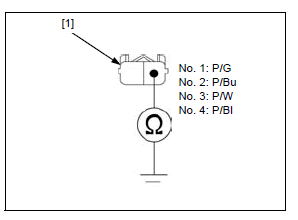

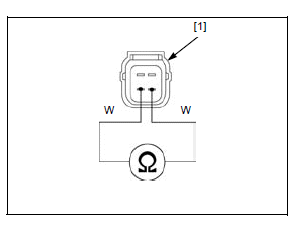

Measure the resistance between the sensor side O2 sensor 4P (Black) connector [1] terminals.

CONNECTION: White - White

STANDARD: 10 - 40 Ω (20ºC/68ºF)

Is the resistance within standard value?

YES - GO TO STEP 3.

NO - Faulty O2 sensor

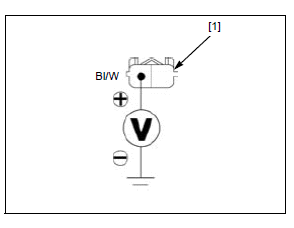

3. O2 Sensor Heater Input Voltage Inspection

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side O2 sensor 4P (Black) connector [1] and ground.

CONNECTION: Black/white (+) - Ground (-)

Is there battery voltage?

YES - GO TO STEP 4.

NO - Open circuit in Black/white wire

4. O2 Sensor Heater Line Open Circuit Inspection

Disconnect the ECM 33P (Gray) connector.

Check the continuity between the wire harness side O2 sensor 4P (Black) connector [1] and ECM 33P (Gray) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Black/blue - Black/blue

Is there continuity?

YES - GO TO STEP 5.

NO - Open circuit in Black/blue wire

5. O2 Sensor Heater Line Short Circuit Inspection

Check the continuity between the wire harness side O2 sensor 4P (Black) connector [1] terminal and ground.

CONNECTION: Black/blue - ground

Is there continuity?

YES - Short circuit in Black/blue wire

NO - Replace the ECM with a known good one, and recheck.

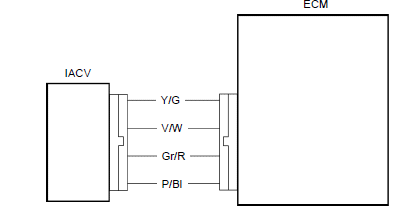

DTC 29 (IACV)

Probable cause

- Open or short circuit in Yellow/green, Violet/white, Gray/red or Pink/black wire between the IACV and ECM

- Faulty IACV

- Faulty ECM

DTC 29-1 (IACV)

- Before starting the inspection, check for loose or poor contact on the IACV 4P (Black) and ECM 33P (Black) connectors, and recheck the DTC.

1. Recheck DTC

Erase the DTC.

Check the IACV with the MCS.

Is the DTC 29-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. IACV Resistance Inspection

Turn the ignition switch OFF.

Lift the fuel tank and support it.

Disconnect the IACV 4P (Black) connector.

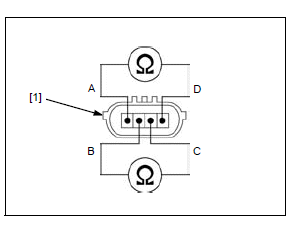

Measure the resistance between the 4P connector terminals of the IACV [1].

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

A - D

B - C

STANDARD: 110 - 150 Ω (25ºC/77ºF)

Is the resistance within standard value?

YES - GO TO STEP 3.

NO - Faulty IACV

3. IACV Internal Short Circuit Inspection

Check for continuity between the 4P connector terminals of the IACV [1].

TOOL: Test probe 07ZAJ-RDJA110

CONNECTION:

A - B

C - D

Is there continuity?

YES - Faulty IACV.

NO - GO TO STEP 4.

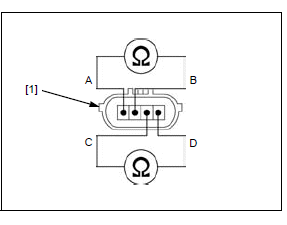

4. IACV Line Open Circuit Inspection

Disconnect the ECM 33P (Black) connector.

Check for continuity between the wire harness side ECM 33P (Black) connector [1] and IACV 4P (Black) connector [2] terminals.

TOOL:

Test probe (2 required) 07ZAJ-RDJA110

CONNECTION:

Yellow/green - Yellow/green

Violet/white - Violet/white

Gray/red - Gray/red

Pink/black - Pink/black

Is there continuity?

YES - GO TO STEP 5.

NO -

- Open circuit in Yellow/green or Violet/ white wire

- Open circuit in Gray/red or Pink/black wire

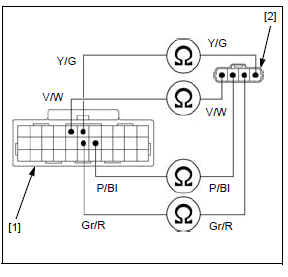

5. IACV Line Short Circuit Inspection Check for continuity between the wire harness side IACV 4P (Black) connector [1] terminals and ground.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION:

Yellow/green - Ground

Violet/white - Ground

Gray/red - Ground

Pink/black - Ground

Is there continuity?

YES -

- Short circuit in Yellow/green or Violet/ white wire

- Short circuit in Gray/red or Pink/black wire

NO - Replace the ECM with a known good one, and recheck.

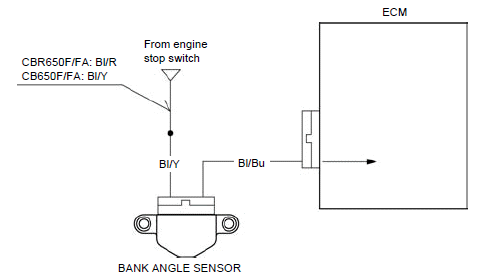

DTC 54 (BANK ANGLE SENSOR)

Probable cause

- CBR650F/FA: Open circuit in Black/red or Black/ yellow wire between the engine stop switch and bank angle sensor

- CB650F/FA: Open circuit in Black/yellow wire between the engine stop switch and bank angle sensor

- Open or short circuit in Black/blue wire between the bank angle sensor and ECM

- Faulty bank angle sensor

- Faulty ECM

DTC 54-1 (BANK ANGLE SENSOR LOW VOLTAGE)

- Before starting the inspection, check for loose or poor contact on the bank angle sensor 2P (Black) and E

1. Bank Angle Sensor System Inspection

Erase the DTC.

Check the bank angle sensor with the MCS.

Is about 0 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

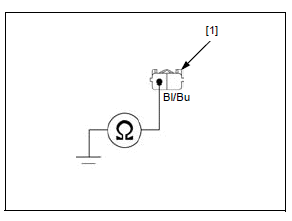

2. Bank Angle Sensor Signal Line Short Circuit Inspection

Turn the ignition switch OFF.

Disconnect the bank angle sensor 2P (Black) connector.

Check for continuity between the wire harness side bank angle sensor 2P (Black) connector [1] terminal and ground.

CONNECTION: Black/blue - Ground

Is there continuity?

YES - Short circuit in the Black/blue wire.

NO - GO TO STEP 3.

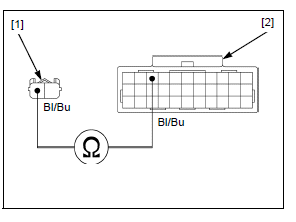

3. Bank Angle Sensor Signal Line Open Circuit Inspection

Disconnect the ECM 33P (Gray) connector.

Check for continuity between the wire harness side bank angle sensor 2P (Black) connector [1] and ECM 33P (Gray) connector [2] terminals.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: Black/blue - Black/blue

Is there continuity?

YES - GO TO STEP 4.

NO - Open circuit in the Black/blue wire

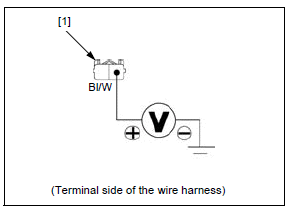

4. Bank Angle Sensor Input Voltage Inspection

Temporarily install the ECM to the wire harness by connecting the 33P (Black) connector.

Turn the ignition switch ON with the engine stop switch " ".

".

Measure the voltage between the wire harness side bank angle sensor 2P (Black) connector [1] terminal and ground.

CONNECTION: Black/white (+) - Ground (-)

Is there battery voltage?

YES - GO TO STEP 5.

NO - Open circuit in Black/white wire

5. Bank Angle Sensor Inspection

Check the bank angle sensor.

Is the bank angle sensor normal?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty bank angle sensor

DTC 54-2 (BANK ANGLE SENSOR HIGH VOLTAGE)

1. Bank Angle Sensor System Inspection

Erase the DTC.

Check the bank angle sensor with the MCS.

Is about 5 V indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. Bank Angle Sensor Inspection

Replace the bank angle sensor with a known good one.

Erase the DTC.

Check the bank angle sensor with the MCS.

Is DTC 54-2 indicated?

YES - Replace the ECM with a known good one, and recheck.

NO - Faulty original bank angle sensor

DTC 86 (SERIAL COMMUNICATION MALFUNCTION)

NOTE:

- Before starting the inspection, check the following connectors for loose

or poor contact and the fuse for blown.

- Front sub harness 12P (Black) and 6P (Black)

- ECM 33P (Black) and 33P (Gray)

- Combination meter 16P (Gray)

- METER TAIL LICENSE PO fuse (7.5 A)

- ODO/TURN fuse (7.5 A)

DTC 86-1 (SERIAL COMMUNICATION)

1. Recheck DTC

Erase the DTC.

Check the serial communication with the MCS.

Is DTC 86-1 indicated?

YES - GO TO STEP 2.

NO - Intermittent failure

2. ECM Serial Communication Output Voltage Inspection

Turn the ignition switch OFF.

Remove the following:

- Left upper cowl A (CBR650F/FA)

- Left tank shroud A (CB650F/FA)

Disconnect the front sub wire harness 12P (Black) connector [1].

Short the DLC terminals using the SCS connector.

Open the throttle grip fully, hold it and turn the ignition switch ON with the

engine stop switch " ".

".

Wait for more than 10 seconds and release the throttle grip.

NOTE:

- The ECM enters the communication diagnostic output mode. The open circuit in the ECM can be checked in this mode.

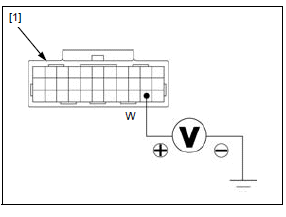

Measure the voltage between the main wire harness side 12P (Black) connector [1] terminal and ground.

CONNECTION: White (+) - ground (-)

Does the voltage repeat 0 V to 8 V or more at intervals of 5 seconds?

YES - GO TO STEP 3.

NO - Replace the ECM with a known good one, and recheck.

3. Combination Meter Serial Communication Output Voltage Inspection

Turn the ignition switch OFF.

Remove the SCS connector.

Connect the front sub harness 12P (Black) connector.

Disconnect the ECM 33P (Gray) connector.

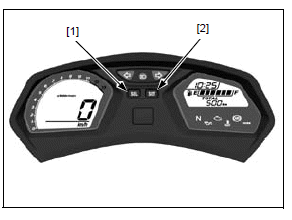

Push and hold combination meter buttons SEL [1] and SET [2], turn the ignition

switch ON with the engine stop switch " ".

".

Wait for more than 10 seconds and release the buttons.

NOTE:

- The combination meter enters the communication diagnostic output mode. The open circuit in the combination meter can be checked in this mode.

Measure the voltage between the wire harness side ECM 33P (Gray) connector [1] terminal and ground.

TOOL:

Test probe 07ZAJ-RDJA110

CONNECTION: White (+) - Ground (-)

Does the voltage repeat 0 V to 8 V or more at intervals of 5 seconds?

YES - GO TO STEP 4.

NO - Replace the combination meter with a known good one, and recheck.

4. Combination Meter Back-up Voltage Inspection

Turn the ignition switch OFF.

Disconnect the combination meter 16P (Gray) connector.

Connect the front sub harness 12P (Black) connector (CB650F/FA only).

Measure the voltage between the combination meter 16P (Gray) connector [1] terminal and ground.

CONNECTION: Red/white (+) - Ground (-)

Is there battery voltage?

YES - Intermittent failure

NO - Open circuit in Red/white wire between the fuse box 2 and combination meter

See also:

Honda CBR650 - Service manual > PGM-FI troubleshooting information/symptom troubleshooting

Honda CBR650 - Service manual > PGM-FI troubleshooting information/symptom troubleshooting

PGM-FI troubleshooting information GENERAL TROUBLESHOOTING Intermittent Failure The term "intermittent failure" means a system may have had a failure, but it checks OK now. If the MIL does not come on, check for poor contact or loose pins at all connectors related to the circuit that of the troubleshooting. If the MIL was on, but then went out, the original problem may be intermittent.

Honda CBR650 - Service manual > MIL circuit troubleshooting/ECM

Honda CBR650 - Service manual > MIL circuit troubleshooting/ECM

MIL circuit troubleshooting Check that the MIL [1] comes on for 2 seconds and goes off when the ignition switch is turned ON with the engine stop switch "".

Rider's Manual BMW R 1250 GS GSA

Rider's Manual BMW R 1250 GS GSA Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight

Owner's Manual Harley-Davidson Sportster XL1200X Forty-Eight Owner's Manual Honda CBR650R

Owner's Manual Honda CBR650R Service manual Honda CBR650

Service manual Honda CBR650 Owner's Manual Honda PCX125

Owner's Manual Honda PCX125 Owner's Manual Kawasaki Z1000SX

Owner's Manual Kawasaki Z1000SX Service manual Kawasaki Z1000SX

Service manual Kawasaki Z1000SX Owner's Manual Lexmoto Echo

Owner's Manual Lexmoto Echo Owner's Manual Royal Enfield Interceptor 650

Owner's Manual Royal Enfield Interceptor 650 Service manual Royal Enfield Interceptor 650

Service manual Royal Enfield Interceptor 650 Owner's Manual Yamaha MT-07

Owner's Manual Yamaha MT-07